Simon Pepper, Managing Director of ASSDA Member SILA Global, provides an important update on shipping and logistics in the Australian supply chain.

To say the last few years have been unstable, uncertain, difficult, and perturbing would be an understatement. The worldwide impact and far reach of industry issues experienced remind us that we truly are a global economy, and an event on the other side of the world can severely affect the Australian supply chain. We are not out of the woods yet.

Problems that occurred last year with freight rates, space constraints, rollovers, port closures and other delays are beginning

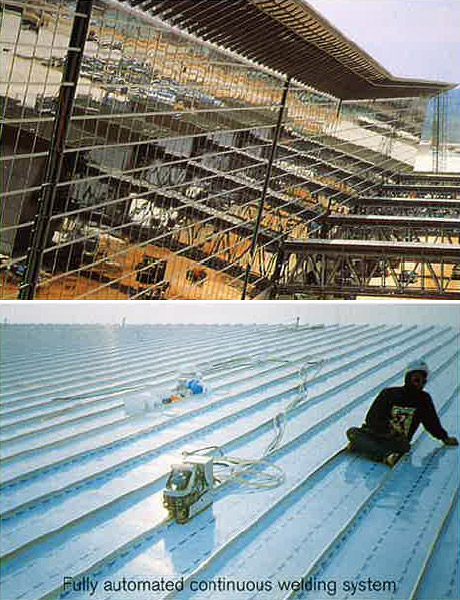

The roof profile of the contact piers and air bridges (60,000m2 total area) had to satisfy a number of criteria, including rainwater runoff, resistance to wind uplift, and a smooth, painted appearance. The roof area comprises a composite system with an outer metal membrane of fully-welded stainless steel. Further complicating the design, the architect (MJAC) wanted to avoid valley gutters on the roof's curves.

The roof profile of the contact piers and air bridges (60,000m2 total area) had to satisfy a number of criteria, including rainwater runoff, resistance to wind uplift, and a smooth, painted appearance. The roof area comprises a composite system with an outer metal membrane of fully-welded stainless steel. Further complicating the design, the architect (MJAC) wanted to avoid valley gutters on the roof's curves.

Flameproofing of material handling equipment is the science of reducing the risk of an explosion or fire by means of specialised principles and technologies.

Flameproofing of material handling equipment is the science of reducing the risk of an explosion or fire by means of specialised principles and technologies.

McMartin, who also won the championship in 2001 and 2002, rode his Ducati Sydney 999S to his third victory at the final round held in September 2004 at Phillip Island, Victoria.

McMartin, who also won the championship in 2001 and 2002, rode his Ducati Sydney 999S to his third victory at the final round held in September 2004 at Phillip Island, Victoria.

Following a tender process, Contractors AW Edwards appointed ASSDA Accredited Fabricator Townsend Group to design, engineer, manufacture

Following a tender process, Contractors AW Edwards appointed ASSDA Accredited Fabricator Townsend Group to design, engineer, manufacture