The common austenitic grades of stainless steel, 304 and 316, are also available with controlled low or high carbon contents, known as "L" and "H" variants, with particular applications.

Low carbon or "L" grades are used to prevent or delay sensitisation of stainless steel at elevated temperatures and the resulting lower corrosion resistance. The problematic temperature zone is 450-850oC, encountered during welding or specific application environments. "L" grades are often available in thicker selection sizes, greater than about 5mm in flat products.

High carbon or "H" grades are used for higher strength.

Substitution between standard, "L" and "H" grades is often possible allowing many specifications to be met from existing stock.

What "L" Grades are used and why are they used?

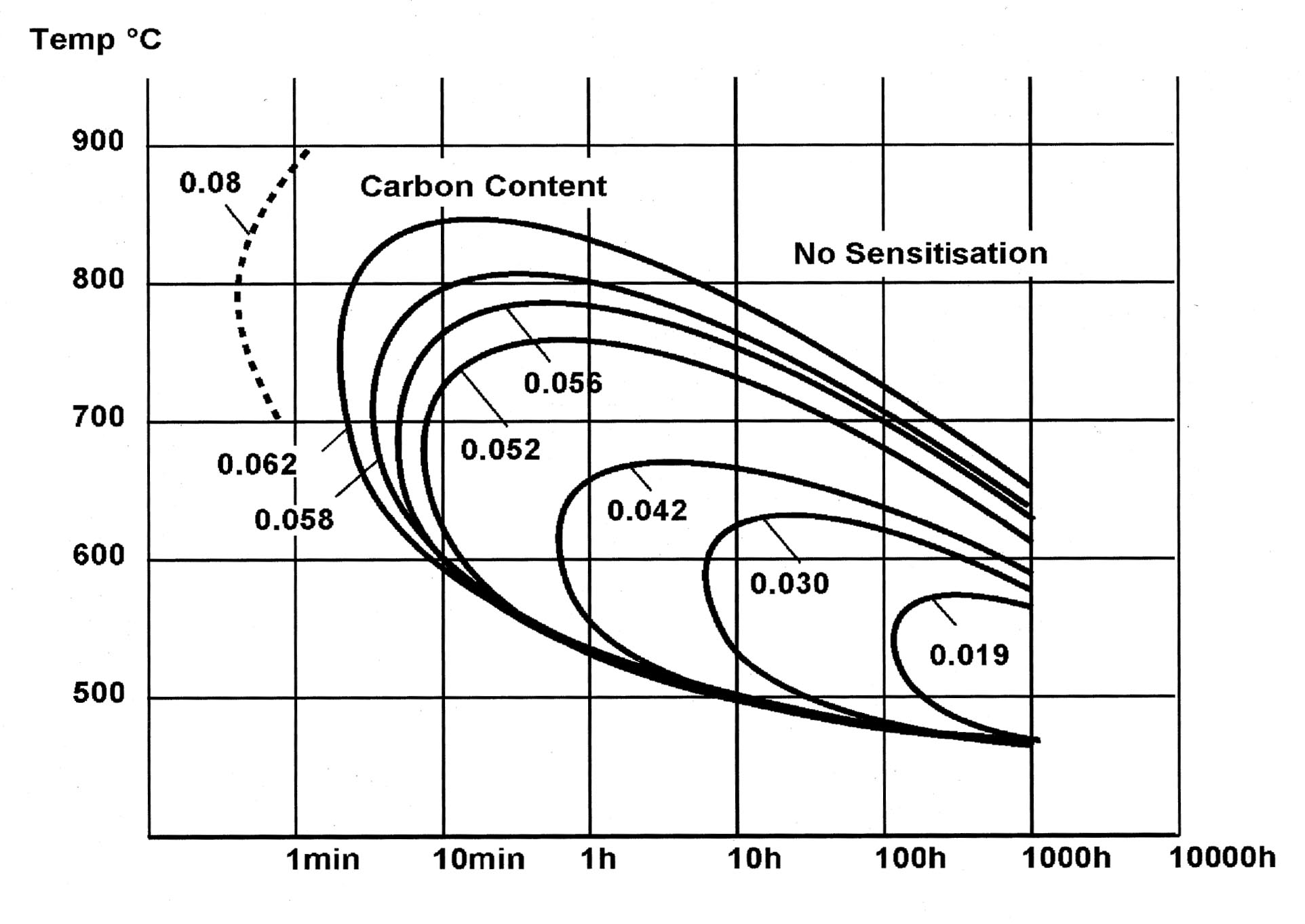

The low carbon "L" grades are used where high temperature exposure will occur, including welding of medium or heavy sections. The low carbon is one way of delaying or preventing grain boundary carbide precipitation (often referred to as sensitisation) which can result in intergranular corrosion in corrosive service environments. As shown in the time-temperature-sensitisation curve (below), there is an incubation time before the precipitation of carbides at temperatures in the range of about 450-850oC. The time for precipitation to occur is highly dependent upon the amount of carbon present in the steel, so low carbon content increases resistance to this problem. Because of their application area the "L" grades are most readily available in plate and pipe, but often also in round bar. In the absence of heavy section welding, or of high temperature exposure, the corrosion resistances of the standard and "L" grades are usually identical.

What "H" Grades are used and why are they used?

"H" grades are higher carbon versions of standard grades and have increased strength, particularly at elevated temperatures (generally above 500oC). Long term creep strength is also higher. "H" grades are primarily available in plate and pipe. Applicable grades are most commonly 304H and 316H, but high carbon versions of 309, 310, 321, 347 and 348 are specified in ASTM A240/A240M. These grades are susceptible to sensitisation if held in the temperature range of 450-850oC. Once sensitised, impaired aqueous corrosion resistance and some reduction in ambient temperature ductility and toughness will result (usually irrelevant in high temperature applications).

What are the differences?

1. Composition limits for 304 and 304L are identical except for carbon content (304L does permit up to 12.0%Ni, compared to 10.5% max for 304 - but given the cost of nickel it is usual for both grades to have close to the minimum of 8.5%, so there is no practical difference). Neither grade has a minimum carbon content specified. A carbon content of 0.02% for example complies with both 304 and 304L specifications.

2. 304H has the same composition specification as 304 except for the carbon range of 0.04-0.10% (note the minimum limit for carbon) and that the 304H does not have the 0.10% nitrogen maximum limit which applies to both standard and "L" grades. Also, all austenitic "H" grades must have a grain size of ASTM No. 7 or coarser.

3. The relationship between 316, 316L and 316H is the same as that between the 304 series of stainless steels. Only the carbon contents differentiate 316, 316L and 316H grades (and the nitrogen and grain size limits mentioned above). Carbon contents are listed in Table 1 (from ASTM A240/A240M). Specifications for some other products, particularly tube and pipe, have a carbon limit of 0.035% or 0.040% maximum for 304L and 316L, but are otherwise the same.

4. Mechanical property specification differences are illustrated in Table 2 (from ASTM A240/A240M). In practice, steel mills generally ensure that the "L" grade heats meet the strength requirements of standard grades, i.e. all 304L will have yield/tensile properties above 205/515MPa, so will meet both standard and "L" grade requirements.

5. Dimensional and other requirements are the same for standard, "L" and "H" grades.

6. Pressure Vessel codes (e.g. AS1210) and Pressure Piping codes (eg AS4041) give allowable working pressures for each of the grades at nominated elevated temperatures. These codes allow higher pressure ratings for standard grades than for "L" grades. The codes do not permit the use of "L" grades above 525oC (AS4041) or 425oC (AS1210). Both codes include a clause stating that for use above 550oC the standard grades must contain at least 0.04% carbon. 304 or 316 material with 0.02% carbon are therefore not permitted for these elevated temperatures, whether called "L" or not. At temperatures from ambient up to this high temperature cut-off "L" grade heats with the standard grade pressure ratings would be permitted, so long as the material was in full compliance with the standard grade composition and mechanical property specifications. As discussed above, it is normal practice for this condition to be met.

7. The pressure vessel codes give the same allowable pressure rating for "H" grades as for standard grades - this is logical as the "H" grades are simply the standard grades with their carbon contents controlled to the top half of the range, or slightly above.

|

Table 1: Carbon Content (ASTM A240/A240M) |

||

| Grade | UNS Number | Specified Carbon Content (%) |

| 304 | S30400 | 0.08 max |

| 304L | S30403 | 0.030 max |

| 304H | S30409 | 0.04-0.10 |

| 316 | S31600 | 0.08 max |

| 316L | S31603 | 0.030 max |

| 316H | S31609 | 0.04-0.10 |

|

Table 2: Mechanical Property Specification Differences (ASTM A240/A240M) |

||||||

| Grade | UNS Strength (MPa) min | Tensile Strength (MPa) min |

Yield (%) min | Elongation Hardness (HB) max | Brinell Hardness (HRB) max | Rockwell |

| 304 | S30400 | 515 | 205 | 40 | 201 | 92 |

| 304L | S30403 | 485 | 170 | 40 | 201 | 92 |

| 304H | S30409 | 515 | 205 | 40 | 201 | 92 |

| 316 | S31600 | 515 | 205 | 40 | 217 | 95 |

| 316L | S31603 | 485 | 170 | 40 | 217 | 95 |

| 316H | S31609 | 515 | 205 | 40 | 217 | 95 |

Alternative Grade Usage

Because of availability issues it is sometimes desirable to use a product labelled as a standard grade when an "L" or "H" grade has been specified, or vice versa. Substitution can be made under the following conditions:

1. "L" grades can be used as standard grades so long as the mechanical properties (tensile and yield) conform to the standard grade requirements and high temperature strength is not a requirement. "L" grades usually comply with standard grade requirements, but Mills' test certificates need to be checked on a case by case basis. It is common for steel mills to supply "L" heats when standard grades have been ordered. The practice is legitimate and should not present problems to fabricators or end users.

2. Standard grades can be used as "L" grades as long as their carbon content meets the "L" grade maximum limits.

3. It is increasingly common for "dual certified" products to be stocked - particularly in plate, pipe and bar. These materials fully comply with both 304 and 304L or 316/316L. Dual certified product is deliberately intended to fulfill requirements for both standard and "L" grades, but cannot be used in applications for "H" grade. If an application requires an "H" grade, this must be specified at time of order. Standard grades can often be used in place of "H" grades so long as their carbon contents meet the "H" limits (generally 0.04-0.10%). Grain size requirements may have to be satisfied by extra testing. The product and its test certificate may describe it as a standard 304 or 316 unless it was originally manufactured as an "H" grade. Details of the test certificate will confirm grade compliance.

4. "H" grades can be used as standard grades so long as their carbon contents are 0.08% maximum, and nitrogen 0.10% maximum. This is likely, but would need to be checked.

References for Further Reading

AS 1210: Pressure Vessels

AS 4041: Standard Specification for Pressure Piping

ASTM A240/A240M: Heat-resisting Chromium and Chromium-Nickel Stainless Steel Plate, Sheet and Strip for Pressure Vessels