1934 marked the birth of the world’s first stainless steel passenger railcar in the United States, and today it represents over 80% of all passenger railcars in Australia. Stainless steels deliver a sustainable materials solution for the rail industry, offering excellent physical properties including formability and weldability, in addition to its high strength, durability and aesthetic appeal.

The typical lifespan of a passenger railcar is 30 to 35 years, however with a proper maintenance program, stainless steel railcars can last more than 50 years. While only requiring minimal maintenance, dirt and other surface contaminants from daily use can affect the appearance of stainless steel.

ASSDA Member Callington Haven was recently engaged in Sydney to rejuvenate 20-year-old stainless steel passenger railcars back to their original aesthetic using a pickling process.

Pickling is a chemical treatment process applied to the surface of stainless steel to remove contaminants and assist in the formation of a continuous chromium-oxide, passive film.

The process leaves a slight matt finish and provides a passive surface immediately upon rinsing, maximising the ongoing performance, durability and corrosion resistance of stainless steel.

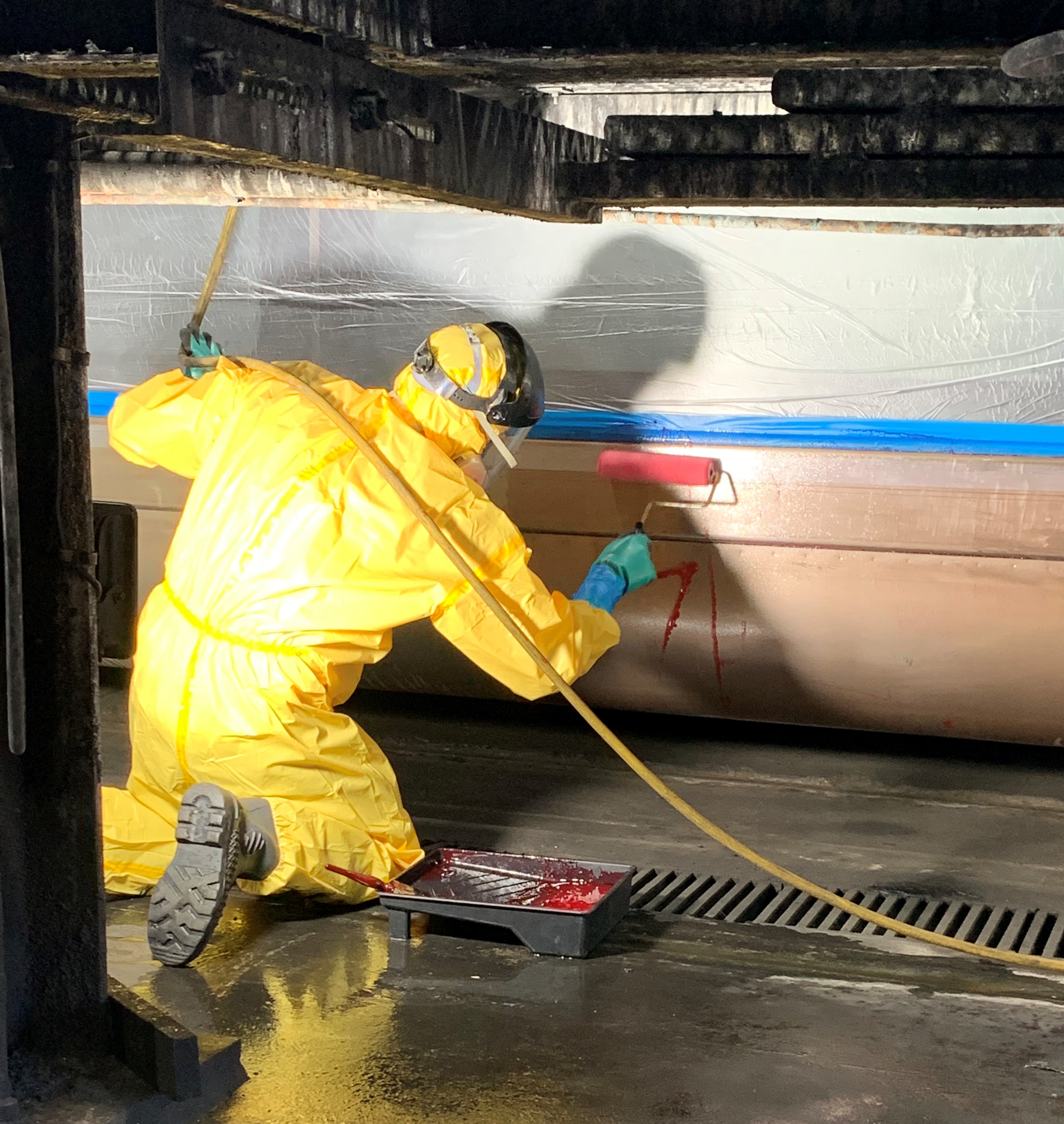

With a controlled application and wash down process in place, the stainless steel passenger railcars’ transformation was performed using Callington Haven’s own S-Weld SPS Pickling Solution.

Following pre-cleaning of the surface with a detergent, the product was applied with a roller to prevent atomisation of the pickling product. After 25 minutes, the solution was soft water blasted and excess pickling agent was removed with a squeegee. A full water blast using clean potable water and dry down of the stainless steel passenger railcars completed the process.

S-Weld SPS Pickling Solution conforms to ASTM A380 (Standard Practice for Cleaning, Descaling and Passivation of Stainless Steel Parts, Equipment and Systems) and has a unique red colouring, allowing operators to know exactly where the product has been applied or if it has been washed down properly.

Pickling solutions usually employ dangerous acids, therefore personal protective equipment was worn by all personnel. For environmental reasons, measures to ensure prevention of run off onto the ground from the application and wash down of the railcars was implemented.

Maintenance is key to preserving public transport and using a pickling process that only took 1.5 hours to perform, Callington Haven delivered an ‘as good as new’ end result for Sydney’s stainless steel passenger railcars.

You can view this story’s pickling process in action at www.youtube.com/watch?v=CV64kea2pBE

Photo credits: Callington Haven

This article is featured in Australian Stainless Magazine issue 73, 2021.