The visual performance of outdoor stainless steel depends on five interrelated factors:

• Surface finish - smooth and clean and free of crevices.

• Grade selection - appropriate for environment.

• Good design - rain washing and uniform draining.

• Maintenance program - regular cleaning.

• End user expectations.

This technical article provides suggestions on a maintenance program for cleaning of exterior stainless steel, together with some recommendations for remedial action if stains occur beyond regular maintenance or where such maintenance has not been performed.

Maintenance: routine removal of grime

Stainless steel holds its appearance best if it is washed regularly. When washing use soap or detergent or 1% ammonia solution in warm, low chloride water with cloths or soft brushes to avoid scratching the surface.

Smears will be reduced if the surface is dried afterwards. This treatment applies to bare stainless steel but care should be taken with coloured surfaces.

Coloured and very smooth finished (eg BA or No. 8) surfaces subjected to excessive brushing or rubbing may lose gloss or even become scratched. Bleaches are not recommended.

Simply wiping with a damp cloth is not adequate as it smears corrosive deposits without removing them.

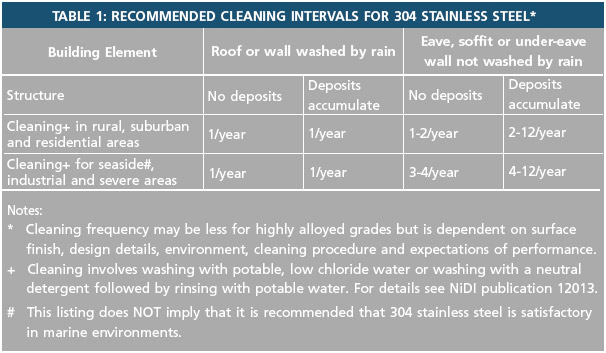

Table 1 from the ASSDA ‘Tea Staining’ Technical Bulletin provides a guide to the recommended frequency for cleaning exterior stainless steel. This Bulletin is available for viewing or download from ASSDA’s website.

Grease, oily films and other organic contamination

Oils and grease may be removed by alkaline formulations or hot water and detergents or, if necessary, by hydrocarbon solvents such as alcohol, acetone or thinners or eucalyptus oil. In all cases the surface should be rinsed with clean water and preferably dried.

For directionally grit polished finishes, wiping along the polish direction with very hot clean water and a soft, absorbent cloth is a good final step to reduce smears.

Heat from a hair dryer or glue gun may soften adhesive remnants from labels or protective films for removal.

After exposure to UV degradation from sunlight, adhesives may require similar treatment to grease stains or even abrasion, with the probability of a bright or scratched spot.

Adherent Scales and Mortar

Adherent scales and mortar may be removed chemically but NOT using chemicals containing chlorides.

NEVER use brick cleaning liquids that contain hydrochloric acid. Hot 25% acetic acid (vinegar) or warm 10% phosphoric acid are effective in removing hard water scales and dried mortar splashes.

Following the acid wash, the surface should be neutralised with dilute ammonia or sodium bicarbonate solution, rinsed and dried.

Remedial Work

The brown surface stains that can occur on stainless steel during atmospheric exposure are simply cosmetic rust stains.

This brown ‘tea staining’ on stainless steels will not progress to potential structural damage as could occur with a carbon steel structure.

The procedures outlined below may enable you to remove the tea staining. However, if the progression of damage is beyond these recommendations it is advisable to employ an experienced contractor.

Cleaning Rust Stained Flat Surfaces

Early action after the onset of tea staining is desirable, before the appearance of the underlying surface is changed.

If the surface is pitted, then it is probable that it will require mechanical repolishing. After mechanically cleaning off tea staining, it is preferable to passivate the surface by using a nitric acid gel or, if the item is portable, by immersion in a nitric acid bath. For marine exposures, passivation is very strongly recommended.

In contrast to other acids, nitric acid is a strong, oxidising acid cleaner and has the added advantage that it is a passivating agent.

The Nickel Institute has suggested that rust may be removed by the use of a 10% phosphoric or oxalic acid followed by a 1% ammonia solution neutralisation and then a water rinse.

Alternatively a mild acid based cleaner such as sulphamic acid (used in some saucepan cleaners) can be used with some care to avoid local changes in appearance. NEVER EVER use hydrochloric or sulphuric acids.

There are also proprietary chemical cleaning treatments often based on citric acid or other chelating compounds. Although these agents passivate in the sense of removing free iron and other foreign matter, they do not augment the surface oxide film.

Use of liquid acids on site is generally unsatisfactory as contact time is short and the acid may run off and damage adjacent components.

Unlike the hydrofluoric acid pickling process used after welding, a nitric acid passivation process does not normally change the surface appearance of stainless steel, although it may cloud a mirror polished surface. Careful trials on inconspicuous areas are recommended prior to full scale cleaning.

Electropolishing is also used by some contractors to smooth rough edges and both clean and passivate the surface. It can be carried out on site or, more usually, in purpose-built tanks.

Afterwards – prevention of recurrence

If tea staining has occurred, one or more of the five factors outlined in the introduction have not been considered carefully enough when the structure was designed and/or built.

To improve the structure, the following steps may be taken to prevent recurrence:

• Increase the frequency of maintenance.

• Improve the surface finish - mechanical polishing and chemical treatment on-site.

• Alter the design of the structure - redesign and replace the affected part of the structure.

• Improve grade selection - replace the structure with a more suitable grade of stainless steel.

ABOVE: A successful stainless steel installation in an outdoor application.

If consideration of the aforementioned steps indicates an uneconomic result, the stainless steel can be painted.

Paint systems using lacquers and polyurethane top coats are available and have been used successfully, but care and understanding is required.

Painting the stainless steel is a step that should only be used as a last option as it is irreversible.

This technical article was published in Australian Stainless Issue 28, May 2004. It is an extract of a Technical FAQ on ‘Exterior Cleaning of Stainless Steel’.

For technical support and advice contact ASSDA on 07 3220 0722 or email