A pilot magnesium processing plant is currently under production in Gladstone, using unique technology developed in Australia and incorporating a significant stainless steel component.

The Australian Magnesium (AM) process (now owned by the Australian Magnesium Corporation - Brisbane, Qld) was jointly developed by Queensland Metals Corporation (QMC - Brisbane, Qld) and CSIRO to process the type of magnesite ore discovered by QMC near Rockhampton into highly pure magnesium metal.

The Australian Magnesium (AM) process (now owned by the Australian Magnesium Corporation - Brisbane, Qld) was jointly developed by Queensland Metals Corporation (QMC - Brisbane, Qld) and CSIRO to process the type of magnesite ore discovered by QMC near Rockhampton into highly pure magnesium metal.

The process incorporates a number of patented features which will be demonstrated and refined at the pilot plant in Gladstone on its completion in mid-1998. The AM process involves the use

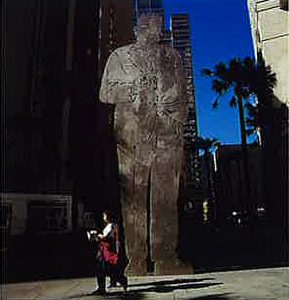

Sydney artist Simeon Nelson designed 'Ben Chifley' and a glass and stainless steel wall on the site while working as part of the multi-disciplinary design team involved in the site's $3 million redevelopment. Hassell architects (Sydney) were given open guidelines for the design of the site, but two of the objectives

Sydney artist Simeon Nelson designed 'Ben Chifley' and a glass and stainless steel wall on the site while working as part of the multi-disciplinary design team involved in the site's $3 million redevelopment. Hassell architects (Sydney) were given open guidelines for the design of the site, but two of the objectives