Our three-part series on coated abrasives concludes with information on choosing the correct abrasive product for the desired finish. Read Part 1. Read Part 2.

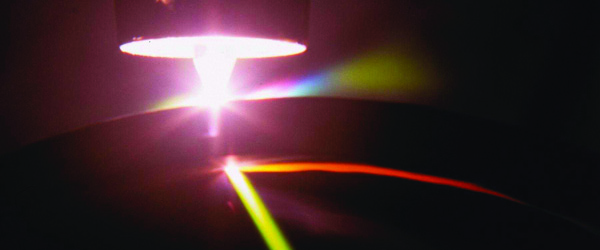

THE IMPORTANCE OF SURFACE ROUGHNESS

The surface roughness of stainless steel is an important factor in determining corrosion resistance. Put simply, the smoother the finish the greater the corrosion resistance, whether in the form of sheet or coil or in welded components.

SURFACE TOPOGRAPHY

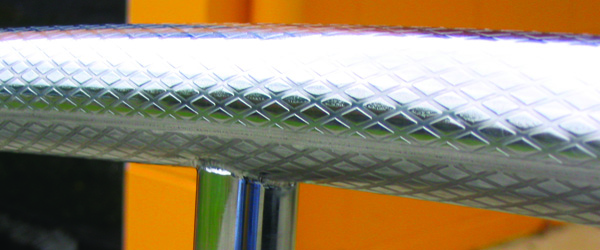

Interaction between the abrasive belt and the workpiece is affected by surface topography (micro texture). Even a surface which appears perfectly flat to the naked eye has ‘asperities’, undulations between 0.05

His choice was 316 stainless steel, finished with specialised surface treatments, combined with translucent blue glass and earthed in basalt.

His choice was 316 stainless steel, finished with specialised surface treatments, combined with translucent blue glass and earthed in basalt.

An Expression of Individuality

An Expression of Individuality

However, Geoff Mellows from Yarrawonga Irrigation in Victoria may have solved the puzzle by using stainless steel mainline fittings - something that plastic fittings cannot yet match.

However, Geoff Mellows from Yarrawonga Irrigation in Victoria may have solved the puzzle by using stainless steel mainline fittings - something that plastic fittings cannot yet match.