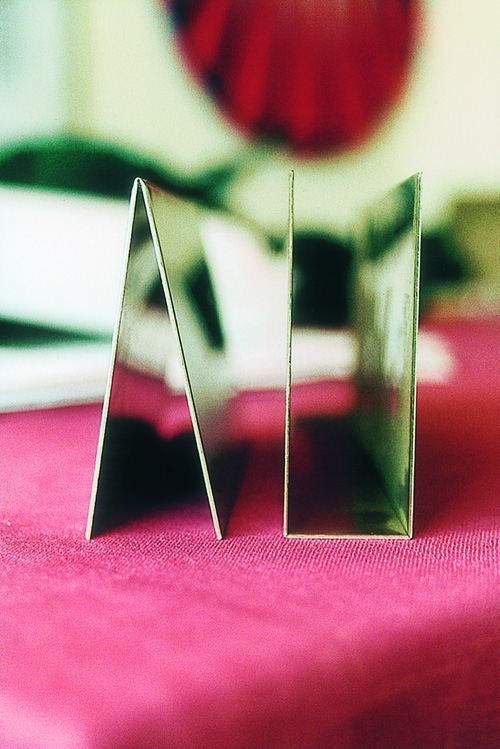

The overwhelming response from the architecture community to our earlier article on precision folding of stainless steel sheet using vee-cutting technology has prompted a more in-depth look at the process.

Thanks to vee-cut technology, stainless steel sheet can be formed into angles as precise as those obtained by extrusion. This technology is now being carried out in Sydney, allowing the local manufacture of a whole range of stainless steel architectural products. The technique is particularly suited to elements such as door fronts, window frames, shopfronts, showcases, elevator doors as well as all forms of cladding.

Thanks to vee-cut technology, stainless steel sheet can be formed into angles as precise as those obtained by extrusion. This technology is now being carried out in Sydney, allowing the local manufacture of a whole range of stainless steel architectural products. The technique is particularly suited to elements such as door fronts, window frames, shopfronts, showcases, elevator doors as well as all forms of cladding.

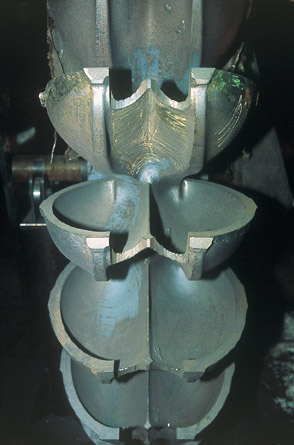

In a completely new method

INSPIRED BY NATURE

INSPIRED BY NATURE

Stainless steel balustrades will preserve open views across to Southbank and back to the CBD while ensuring public safety. These combine subtly

Stainless steel balustrades will preserve open views across to Southbank and back to the CBD while ensuring public safety. These combine subtly

According to the Site Co-ordinator Keith Vanderstaay, the caves "have been reinvented with the completion of a state of the art, computer-controlled lighting system which will change the way everybody will see the cave."

According to the Site Co-ordinator Keith Vanderstaay, the caves "have been reinvented with the completion of a state of the art, computer-controlled lighting system which will change the way everybody will see the cave."

Manufacturing by an Australian firm will also make it easier for specificiers to communicate their special requirements.

Manufacturing by an Australian firm will also make it easier for specificiers to communicate their special requirements.

While the former Premier's impact on the Victorian capital has been comprehensive, the refurbishment of Brighton Sea Baths as an upscale nightspot part-owned by Mr Newman has contributed a smaller scale landmark which is just as likely to provide visitors (male ones, anyway) with a memorable impression of the city.

While the former Premier's impact on the Victorian capital has been comprehensive, the refurbishment of Brighton Sea Baths as an upscale nightspot part-owned by Mr Newman has contributed a smaller scale landmark which is just as likely to provide visitors (male ones, anyway) with a memorable impression of the city.

The originality of the design complements the creative nature of the activities housed in the building, situated on the edge of Adelaide’s Light Square.

The originality of the design complements the creative nature of the activities housed in the building, situated on the edge of Adelaide’s Light Square.

Deck fittings and equipment made in 316 stainless are stronger and more durable than most alternatives. Their lifespan is further enhanced when kept clear of salt encrustations, grease and dirt. This is facilitated by a very smooth surface which doesn't present miniscule pits and crevices where corrosion can begin.

Deck fittings and equipment made in 316 stainless are stronger and more durable than most alternatives. Their lifespan is further enhanced when kept clear of salt encrustations, grease and dirt. This is facilitated by a very smooth surface which doesn't present miniscule pits and crevices where corrosion can begin.

Page’s of the Mall is a stainless steel satellite to an existing cafe located in the busy Launceston Mall. Custom built for the site, it has proved popular and profitable since opening shortly before Christmas 2002.

Page’s of the Mall is a stainless steel satellite to an existing cafe located in the busy Launceston Mall. Custom built for the site, it has proved popular and profitable since opening shortly before Christmas 2002.