Stainless steel is the material of choice to specify for severe weather conditions.

The overhead netting of Perth Zoo's Australian Wetlands and Penguin Plunge Exhibit was badly damaged when a severe hailstorm and winds of up to 128km/h swept through Perth in March 2010.

During the storm, a tree collapsed onto the netting which was made from a nylon material.

The original concept for this major renovation project was to use stainless steel overhead netting and painted or galvanised steel for the cabling and the majority of other supporting infrastructure components.

However, when ASSDA members Structural Dynamics was awarded subcontractor

Having worked with stainless steel for over 25 years, Buttress said that the material’s strength, ability to look good over time with minimal maintenance, and the flexibility of finishes works well both practically and aesthetically.

Having worked with stainless steel for over 25 years, Buttress said that the material’s strength, ability to look good over time with minimal maintenance, and the flexibility of finishes works well both practically and aesthetically.

ject was commissioned by the Gold Coast City Council (GCCC) to redevelop the beachfront area between Laycock Street and View Avenue in Surfers Paradise.

ject was commissioned by the Gold Coast City Council (GCCC) to redevelop the beachfront area between Laycock Street and View Avenue in Surfers Paradise.

Covering 103,000m2, the $1.2 billion Westfield Sydney development is bound by the Pitt Street Mall and Market and Castlereagh Streets in the heart of Sydney’s CBD. It integrates Westfield Centrepoint, the Centrepoint Convention Centre, Imperial Arcade and Skygarden, plus a new office tower at 85 Castlereagh Street and an extensively modified and refurbished tower at 100 Market Street.

Covering 103,000m2, the $1.2 billion Westfield Sydney development is bound by the Pitt Street Mall and Market and Castlereagh Streets in the heart of Sydney’s CBD. It integrates Westfield Centrepoint, the Centrepoint Convention Centre, Imperial Arcade and Skygarden, plus a new office tower at 85 Castlereagh Street and an extensively modified and refurbished tower at 100 Market Street.

Described as the cultural home of the North Shore, The Concourse (Chatswood, NSW) incorporates a concert hall, theatre, library, outdoor urban screen, restaurants and retail stores.

Described as the cultural home of the North Shore, The Concourse (Chatswood, NSW) incorporates a concert hall, theatre, library, outdoor urban screen, restaurants and retail stores.

masonry to the structural backing which supports the wall. The most common wall ties are manufactured out of galvanised steel.

masonry to the structural backing which supports the wall. The most common wall ties are manufactured out of galvanised steel.

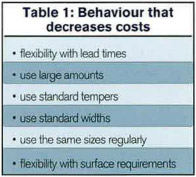

Australia is a relatively 'small fish' in the global stainless industry and, without the benefit of local stainless steel production, loses some flexibility on product availability. Unless you're a very large consumer of stainless steel to a single specification or Standard, ordering to common specifications will reduce costs and increase availability of products.

Australia is a relatively 'small fish' in the global stainless industry and, without the benefit of local stainless steel production, loses some flexibility on product availability. Unless you're a very large consumer of stainless steel to a single specification or Standard, ordering to common specifications will reduce costs and increase availability of products. Suppliers are likely to have products to common specifications. Ordering them reduces the

Suppliers are likely to have products to common specifications. Ordering them reduces the

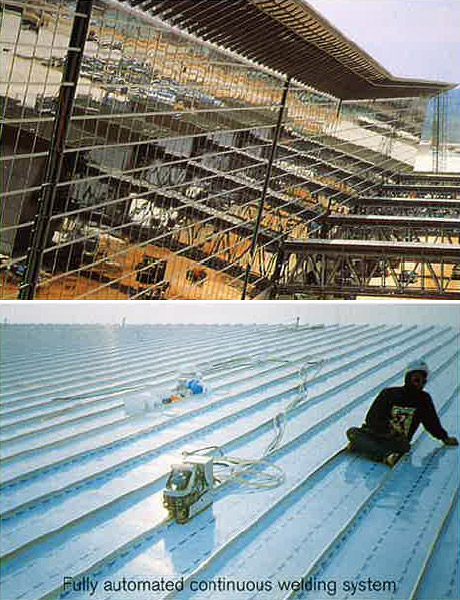

The roof profile of the contact piers and air bridges (60,000m2 total area) had to satisfy a number of criteria, including rainwater runoff, resistance to wind uplift, and a smooth, painted appearance. The roof area comprises a composite system with an outer metal membrane of fully-welded stainless steel. Further complicating the design, the architect (MJAC) wanted to avoid valley gutters on the roof's curves.

The roof profile of the contact piers and air bridges (60,000m2 total area) had to satisfy a number of criteria, including rainwater runoff, resistance to wind uplift, and a smooth, painted appearance. The roof area comprises a composite system with an outer metal membrane of fully-welded stainless steel. Further complicating the design, the architect (MJAC) wanted to avoid valley gutters on the roof's curves.