If a job requires greater corrosion resistance than grade 304 can provide, grade 316 is the 'next step up'. Grade 316 has virtually the same mechanical, physical and fabrication characteristics as 304 with better corrosion resistance, particularly to pitting corrosion in chloride environments.

Grade 316 (U NS S31600) is the second most popular grade accounting for about 20% of all stainless steel produced.

This article follows on from "304 -the place to start" in Issue 10 which is also available on ASSDA's website at www.assda.asn.au

COMPOSITION

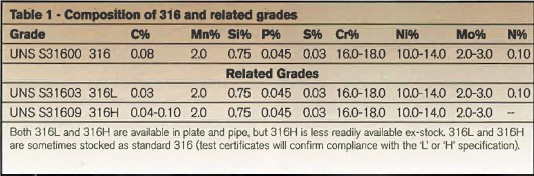

Table 1 compares three related grades - 316, 316L and 31 6H.

Grade 316L is a low carbon 316 often used to avoid possible sensitisation corrosion in welded components.

Grade 316H has a higher carbon content than 316L, which increases the strength (particularly at temperatures above about 500°C), but should not be used for applications where sensitisation corrosion could be expected.

Both 316L and 316H are available in plate and pipe, but 316H is less readily available ex-stock. 316L and 316H are sometimes stocked as standard 316 (test certificates will confirm compliance with the 'L' or 'H' specification).

CORROSION RESISTANCE

Grade 316 has excellent corrosion resistance in a wide range of media. Its main advantage over grade 304 is its increased ability to resist pitting and crevice corrosion in warm chloride environments. It resists common rusting in virtually all architectural applications, and is often chosen for more aggressive environments such as seafront buildings and fittings on wharves and piers. It is also resistant to most food processing environments, can be readily cleaned, and resists organic chemicals, dye stuffs and a wide variety of inorganic chemicals.

In hot chloride environments, grade 316 is subject to pitting and crevice corrosion and to stress corrosion cracking when subjected to tensile stresses beyond about 50°C. In these severe environments duplex grades such as 2205 (UNS S31803) or higher alloy austenitic grades including 6% molybdenum (UNS S31254) grades are more appropriate choices.

The corrosion resistances of the high and low carbon versions of 316 (316L and 316H) are the same as standard 316.

HEAT RESISTANCE

Like grade 304, 316 has good oxidation resistance in intermittent service to 870°C and in continuous service to 925°C. Continuous use of 316 in the 425-860°C range is not recommended if subsequent exposure to room temperature aqueous environments is anticipated, but it often performs well in temperatures fluctuating above and below this range.

Grade 316L is more resistant to carbide precipitation than standard 316 and 316H and can be used in the above temperature range. However, where high temperature strength is important, higher carbon values are required. For example, AS 1210 Pressure Vessels Code limits the

operating temperature of 316L to 450°C and restricts the use of 316 to carbon values of 0.04% or higher for temperatures above 550°C. 316H or the titanium-containing version 316Ti can be specified for higher temperature applications.

316 has excellent toughness down to temperatures of liquefied gases and has application at these temperatures, although lower cost grades such as 304 are more usually selected for cryogenic vessels.

PHYSICAL AND MECHANICAL PROPERTIES (see Tables 2 and 3)

PHYSICAL AND MECHANICAL PROPERTIES (see Tables 2 and 3)

Like other austenitic grades, 316 in the annealed condition is virtually nonmagnetic (ie. very low magnetic permeability). While 304 can become significantly attracted to a magnet after being cold worked, grade 316 is almost always virtually totally non-responsive. This may be a reason for selecting grade 316 in some applications.

Annealing (also referred to as solution treating) is the main heat treatment carried out on grade 316. This is done by heating to 1,010-1,120°C and rapidly cooling - usually by water quenching.

FABRICABILITY

316 can be deep drawn without intermediate heat softening enabling it to be used in the manufacture of drawn stainless parts, such as sinks and saucepans. However, for normal domestic articles the extra corrosion resistance of grade 316 is not necessary. 316 is readily brake or roll formed into a variety of other parts for application in the industrial and architectural fields.

Grade 316 has outstanding weldability and all standards welding techniques can be used. Although post-weld annealing is often not required to restore 316's corrosion resistance (making it suitable for heavy gauge fabrication) appropriate post-weld clean-up is recommended.

Grade 316 has outstanding weldability and all standards welding techniques can be used. Although post-weld annealing is often not required to restore 316's corrosion resistance (making it suitable for heavy gauge fabrication) appropriate post-weld clean-up is recommended.

Machinability of 316 is lower than most carbon steels. The standard austenitic grades like 316 can be readily machined if slower speeds and heavy feeds are used, tools are rigid and sharp, and cutting fluids are involved. An 'improved machinability' version of 316 also exists.

COST COMPARISONS

The guidelines in Table 4 are approximate 'first cost' comparisons for sheet material in a standard mill finish suitable for construction projects. The appeal of stainless over its first cost competitors dramatically increases

when lifecycle costs are considered.

FORMS AVAILABLE

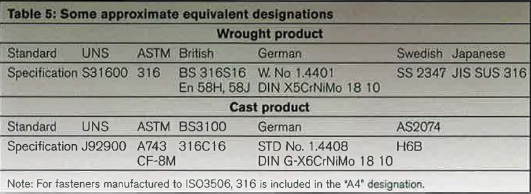

Grade 31 6 is available in virtually all stainless product forms including coil, sheet, plate, strip, tube, pipe, fittings, bars, angles, wire, fasteners and castings. 316L is also widely available, particularly in heavier products such as plate, pipe and bar. Most stainless steel surface finishes, from standard to special finishes, are available.

APPLICATIONS Typical applications for 316 include boat fittings and structural members; architectural components particularly in marine, polluted or industrial

Typical applications for 316 include boat fittings and structural members; architectural components particularly in marine, polluted or industrial

environments; food and beverage processing equipment; hot water systems; and plant for chemical, petrochemical, mineral processing, photographic and other industries.

Although 316 is often described as the 'marine grade', it is also seen as the first step up from the basic 304 grade.

Alternative grades to 316 should be considered in certain environments and applications including:

• strong reducing acids (alternatives might be 904L, 2205 or a super duplex grade),

• environments with temperatures above 50-60°C and with chlorides present (choose grades resistant to stress corrosion cracking and higher pitting resistance such as 2205 or a super duplex or super austenitic), and

• applications requiring heavy section welding (316L), substantial machining (an improved machinability version of 316), high strength or hardness (perhaps a martensitic or precipitation hardening grade).

This technical article featured in Australian Stainless magazine - Issue 13, May 1999.