ASSDA member and Accredited Fabricator Stainless Metal Craft has recently completed work on the design and fabrication of stainless steel equipment for Inghams Enterprises’ processing plant at Edinburgh Park, north of Adelaide, and hatchery at Monarto, south of Adelaide.

ASSDA member and Accredited Fabricator Stainless Metal Craft has recently completed work on the design and fabrication of stainless steel equipment for Inghams Enterprises’ processing plant at Edinburgh Park, north of Adelaide, and hatchery at Monarto, south of Adelaide.

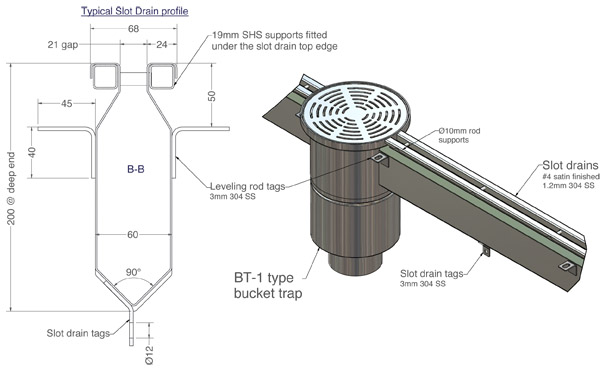

The projects incorporate numerous custom-designed installations, including a series of 300mm wide channelled drainage at the processing plant in runs of 60m that will withstand the weight of forklifts, and slot drains with integrated sumps (Figure 1) at the hatchery that will tolerate extremely harsh cleaning compounds.

Stainless Metal Craft General Manager Graeme Bunt said the slot drains, in particular, were a specialised project requiring innovative tool work, because of the size and depth required.

He said the slot drains were fabricated at their facility at Emu Plains, NSW, then shipped to Adelaide in 8m lengths where they were site welded to form continuous drains of 44m.

Mr Bunt said grades 304 and 316 were both used at the facilities, depending on the application.

“For most of the general usage areas, such as laundry chutes, bump rails, hand rails, hands-free wash stations, walk-through showers and chequer plate platforms and stairs, we were able to use 304,” Mr Bunt said.

“But in more specialised areas or where harsh chemicals may be used, such as slot drains, some clean points, freezer coving, boot washers and fire hose reel cabinets, we had to use 316 to ensure the material would withstand the harsh environment.”

Mr Bunt said freezer coving (a hygiene requirement to prevent food from being caught where the wall meets the floor) is usually made from epoxy-coated concrete, but there was concern this would wear down with ongoing snap freezing of the chickens. Instead, about 180m of 3mm grade 316 were used.

Strict regulations within the food industry also determined the need for grade 316 stainless steel fire hose reel cabinets.

Mr Bunt said most of the stainless steel was supplied by ASSDA members Atlas Specialty Metals and Midway Metals. The processing plant was handed over to Inghams at the end of September and the hatchery will also be handed over this year.

STAINLESS STEEL STATISTICS

Further Processing Plant

• 55 hands-free wash stations

• 80 clean points

• 180 metres of freezer coving

• 12 boot washers

• 18 fire hose reel cabinets

• 300mm wide channelled drainage in runs of 60 metres – strong enough to withstand weight of forklifts

Hatchery

• 495 metres of slot drains

• 10 hands-free wash stations

• 800 metres of Schedule 40 pipe bump rails

• 45 clean points

• 7.7 square metre egg shell hopper

This article featured in Australian Stainless Issue 41